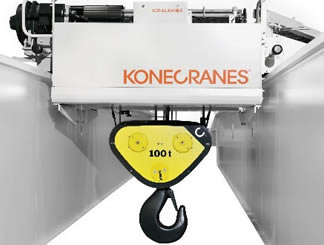

Electric hoists are mechanical devices used for lifting and lowering heavy loads in a controlled manner. They are powered by electricity and typically consist of a motor, gearbox, brake system, wire rope or chain, hook or lifting attachment, and a control system. Electric hoists come in various configurations, such as wire rope hoists and chain hoists, offering different lifting capacities and functionalities to cater to a wide range of applications. Read More…

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

Bridge Crane Specialists offers a select inventory of used and surplus crane and hoist products which includes used overhead cranes, used hoists, and other parts available for purchase. Browse our selection of used products listed below or contact us to ask about our expanding inventory of new, used, and surplus cranes, hoists, parts, and other overhead crane components.

At Simmers, we handle electric hoist projects from start to a turnkey finish. We will supply all equipment through our network of vendors and fabricate the crane at one of our facilities. We also offer field installation after the crane is built. Our highly qualified and trained staff will design a crane that meets your needs and CMAA design standards. For more information on how Simmers crane...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Electric Hoist Manufacturers

Electric hoists find widespread use in numerous industries and settings. They are commonly employed in manufacturing facilities, construction sites, warehouses, and ports for moving materials, equipment, and products. Their ability to lift heavy loads with precision and ease makes them invaluable in assembling heavy machinery, loading and unloading cargo, and erecting structural components. Electric hoists are also prevalent in maintenance and repair work, allowing technicians to lift and position large components with precision and safety. Their versatility, ease of operation, and capacity to handle heavy weights make electric hoists an essential tool for various lifting tasks across different industries.

Components of Electric Hoists

As discussed, an electric hoist consists of several essential components, each playing a crucial role in its functioning. To start, the motor serves as the powerhouse, converting electrical energy into mechanical power to drive the hoisting mechanism. The brake system, meanwhile, acts as a safety feature, preventing unintended lowering of the load when the motor is not running and maintaining stability during lifting operations. The gearbox is responsible for reducing the motor’s high-speed rotation to achieve the necessary torque for lifting heavy loads efficiently.

The wire rope or chain is the primary lifting medium, providing the connection between the hoist and the load. It is designed to handle substantial weight and ensures safe and reliable lifting. The hook or lifting attachment is the component that directly holds the load and must be appropriately designed and rated to avoid any accidents or failures during lifting.

The control system is the brain of the electric hoist, allowing the operator to manage the lifting process. It enables the operator to control the hoist’s movement, speed, and direction, ensuring precise and safe load handling. Additionally, modern electric hoists may include safety features like limit switches, overload protection, and emergency stop buttons to enhance operational safety.

Apart from these primary components, electric hoists may also include additional elements such as load sensors or load cells to provide real-time weight information, helping the operator make informed decisions during lifting operations. Remote control systems may also be employed to improve flexibility and safety, allowing the operator to control the hoist from a distance, reducing the risk of accidents in hazardous environments.

Overall, the integration of these various components ensures that an electric hoist operates efficiently, safely, and reliably, making it an indispensable tool in various industries for lifting and moving heavy loads.

Types of Electric Hoists

There are several types of electric hoists, including wire rope hoists, chain hoists, mini electric hoists, and explosion-proof electric hoists. These types are explained below.

Wire Rope Hoists

Wire rope hoists use a steel wire rope as the lifting medium. They are suitable for heavy-duty lifting applications and are designed to handle substantial loads with high precision. Wire rope hoists offer smooth lifting and lowering operations due to the flexibility and strength of the wire rope. Their lifting capacity can range from a few hundred kilograms to several tons, making them ideal for industrial and construction purposes. The benefits of wire rope hoists include higher lifting heights, better resistance to abrasion and wear, and greater durability in demanding environments. However, they may require periodic maintenance to check and replace the wire rope, and they can be more expensive than chain hoists.

Chain Hoists

Chain hoists utilize a chain as the lifting medium. They are generally more compact and lighter than wire rope hoists, making them more portable and easier to install in confined spaces. Chain hoists are well-suited for a variety of lifting tasks, ranging from light to moderate loads. They are commonly used in workshops, warehouses, and automotive applications. Chain hoists offer simplicity and reliability in their design, and they are generally more cost-effective than wire rope hoists. However, they may have a limited lifting height compared to wire rope hoists, and the chain may be more prone to wear and fatigue over time, necessitating replacement.

Mini Electric Hoists

Mini electric hoists are compact and lightweight versions of electric hoists, designed for handling smaller loads. They are often used in residential or light industrial settings for tasks like lifting household items, small equipment, or light machinery. Their compact size allows for easy installation and storage, and they are typically more affordable than larger electric hoists. However, their lifting capacity is limited compared to standard electric hoists, and they may not be suitable for heavy industrial applications.

Explosion-Proof Electric Hoists

Explosion-proof hoists are specifically designed for hazardous environments where flammable gases, vapors, or dust may be present. These hoists are engineered to prevent sparks or heat generation during operation, reducing the risk of igniting explosive atmospheres. They are commonly used in industries like oil and gas, chemical plants, and mining, where safety is of utmost importance. The major benefit of explosion-proof hoists is their ability to ensure safety in potentially dangerous environments. However, their construction and safety features often make them more expensive than standard electric hoists, and they may have slightly reduced lifting capacities to accommodate additional safety measures.

Considerations Regarding Electric Hoists

While electric hoists offer many benefits, there are also some considerations to take into account. One of the primary factors to consider regarding electric hoists is their initial cost, which can be higher than that of manual hoists or other lifting devices. Additionally, electric hoists require a source of electricity, which may not be readily available in all environments. This can limit their use in outdoor or remote locations. Finally, electric hoists may not be suitable for use in hazardous environments where the risk of explosion or fire is high.

Benefits of Electric Hoists

Electric hoists offer a multitude of benefits that set them apart as essential lifting solutions across various industries. One of their key advantages lies in their exceptional lifting capacity, effortlessly handling heavy loads that would otherwise be challenging or dangerous for workers to lift manually. By reducing the physical strain on operators, electric hoists significantly enhance workplace safety and prevent potential injuries. Their electric motor provides consistent power, ensuring smooth and precise lifting and lowering operations, which is crucial when handling delicate or valuable goods.

Another notable advantage of electric hoists is their versatility. They come in a wide range of configurations, catering to diverse lifting requirements and load capacities. Whether it’s a wire rope hoist for heavy-duty industrial applications, a chain hoist for compact and portable use, or a mini electric hoist for residential tasks, there is an electric hoist suitable for almost any lifting scenario. Their adaptability allows them to be used in manufacturing facilities, construction sites, warehouses, and even in residential settings.

Moreover, electric hoists are designed for ease of operation. Their user-friendly controls enable even inexperienced operators to handle them efficiently, reducing the need for extensive training. This simplicity leads to increased productivity and efficiency in lifting operations. Furthermore, these hoists can be equipped with advanced safety features, such as overload protection, limit switches, and emergency stop buttons. These safety mechanisms help prevent accidents and damage to both the hoist and the load, providing an extra layer of security in the workplace.

An often overlooked benefit of electric hoists is their eco-friendliness. As they are powered by electricity, they produce no harmful emissions, making them a greener option compared to hoists powered by fuel-driven engines.

In summary, the benefits of electric hoists encompass enhanced safety, ease of use, versatility, and eco-friendliness. These qualities make electric hoists an indispensable tool for lifting heavy loads efficiently and safely in various industries, ultimately contributing to increased productivity and a safer work environment.

Applications of Electric Hoists

As a result of these benefits, electric hoists are used in a variety of industries, including:

Manufacturing and Assembly

Electric hoists are commonly used in manufacturing and assembly facilities to lift and move heavy materials or products during the production process. They can be used to move raw materials, work-in-progress, or finished products between different stages of the production line.

Construction

Electric hoists are used in the construction industry to lift and move heavy building materials, such as steel beams, concrete blocks, and prefabricated panels, to different levels of a building site. They can also be used to lift heavy machinery, tools, and equipment to different heights on a construction site.

Warehousing and Logistics

Electric hoists are commonly used in warehouses and logistics centers to lift and move heavy cargo, such as pallets, crates, and containers. They can be used to load and unload trucks, move cargo to different storage locations within the warehouse, and prepare items for shipping.

Automotive

Electric hoists are used in automotive workshops and garages to lift and move cars and other vehicles for repairs and maintenance. They can be used to lift the entire vehicle or specific parts of it, such as the engine or transmission.

Mining and Drilling

Electric hoists are used in mining and drilling operations to lift and move heavy equipment and materials, such as drilling rigs, pipes, and other tools. They can be used in both underground and surface mining operations.

Marine Applications

Electric hoists are used in marine applications, such as shipyards and ports, to lift and move heavy cargo, containers, and other equipment. They can also be used to lift and move boats and other vessels for repairs and maintenance.

Selecting the Correct Electric Hoist

Selecting the right type of electric hoist involves careful consideration of several key factors to ensure that the chosen hoist meets the specific lifting requirements and operating conditions. First, it is essential to determine the maximum load capacity needed for the intended tasks, ensuring the hoist can handle the heaviest load without any strain. Next, the lifting height required should be assessed, considering the distance the load needs to be raised or lowered. Additionally, the available space and installation requirements should be evaluated to choose a hoist that fits the working area and mounting options.

The nature of the application also plays a crucial role in the selection process. For heavy-duty industrial lifting, wire rope hoists may be the best choice due to their high lifting capacity and precision. For more compact spaces or lighter loads, meanwhile, chain hoists might be more suitable. Mini electric hoists are ideal for residential or light commercial use. For hazardous environments with potential explosive atmospheres, explosion-proof hoists are a must for safety compliance.

Considering the frequency of use and the expected workload can help determine whether a more basic or advanced model is required. Safety features, such as overload protection and emergency stop buttons, should not be overlooked, especially in high-risk environments. Finally, it is crucial to select a reputable and reliable manufacturer or supplier to ensure the hoist’s quality, warranty, and customer support.

In conclusion, the process of selecting the right electric hoist involves a thorough assessment of lifting requirements, application, available space, safety features, and budget considerations. By carefully evaluating these factors, one can make an informed decision and choose the most suitable electric hoist for the specific lifting needs, ensuring efficiency, safety, and productivity in the workplace.

Choosing the Correct Electric Hoist Company

To ensure you have the most positive outcome when purchasing an electric hoist from an electric hoist supplier, it is important to compare several companies using our directory of electric hoist suppliers. Each electric hoist supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each electric hoist business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple electric hoist companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches