An overhead hoist is a hoist or crane attached to the ceiling, granary, or structure of a building. They have motors with pulleys, wire ropes, and chains. The motors can be hydraulically, pneumatically, or manually powered. Overhead hoists are widely used for their superior strength and lifting capabilities. Read More…

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

Crane-Tec supplies overhead cranes, hoists, jib cranes and workstations. Some of our hoists include chain hoists, overhead hoists and engineered hoists, and we have a variety of brands such as Yale, Harrington, EMH and more. Call us today for the hoisting equipment you need.

At Crane Equipment & Service, Inc., we take pride in providing a comprehensive range of electric hoists and solutions to meet the diverse lifting needs of industries worldwide. With our commitment to excellence and extensive experience, we have established ourselves as a trusted leader in the field of overhead lifting equipment. Our product lineup encompasses a variety of electric hoists...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Overhead Hoist Manufacturers

Overhead hoists are vertical lifting mechanisms for lifting heavy materials and equipment. The difference between overhead hoists and cranes is the type of lifting they can do. Cranes can move loads vertically and horizontally. However, overhead hoists simply raise items vertically. Overhead hoists are classified by lifting method, power, and suspension system. There are several forms of overhead hoists, including chain hoists, wire rope hoists, manual hoists, electric hoists, and pneumatic hoists.

Types of Overhead Hoist Lift Leverage Tools

When choosing the right hoist for an application, manufacturers consider lifting capacity, mounting type, length of reach, and lift type. Although the hoist was invented in the middle of the first industrial revolution, it wasn’t popular until it could be powered with electricity. Electric power sources increased the lifting capacity and efficiency of hoists and their efficiency.

- Chain Hoists – Chain hoists are the most common type of overhead hoist. They use a chain and a pulley for lifting heavy weights and can be manually powered, electrically powered, or pneumatically powered. Electric chain hoists are the most common.

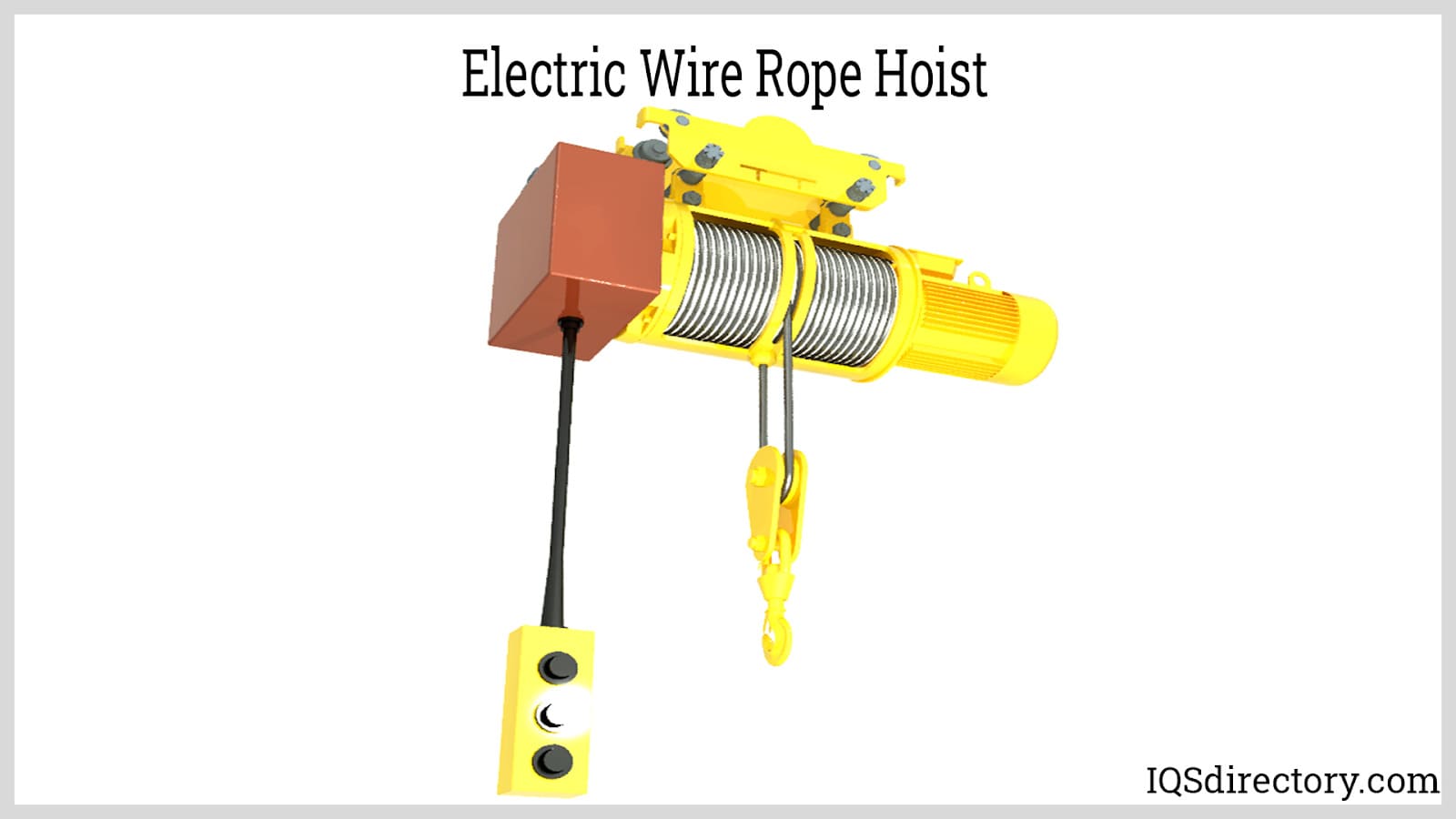

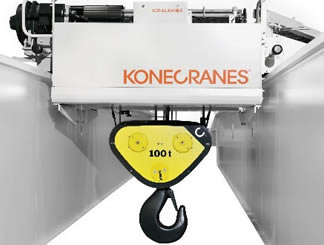

- Wire Rope Hoists use a wire rope for the lifting mechanism. Wire rope offers the strength and stability needed to lift circular drums or boxes without a harness. The majority of wire rope overhead hoists are electrically powered.

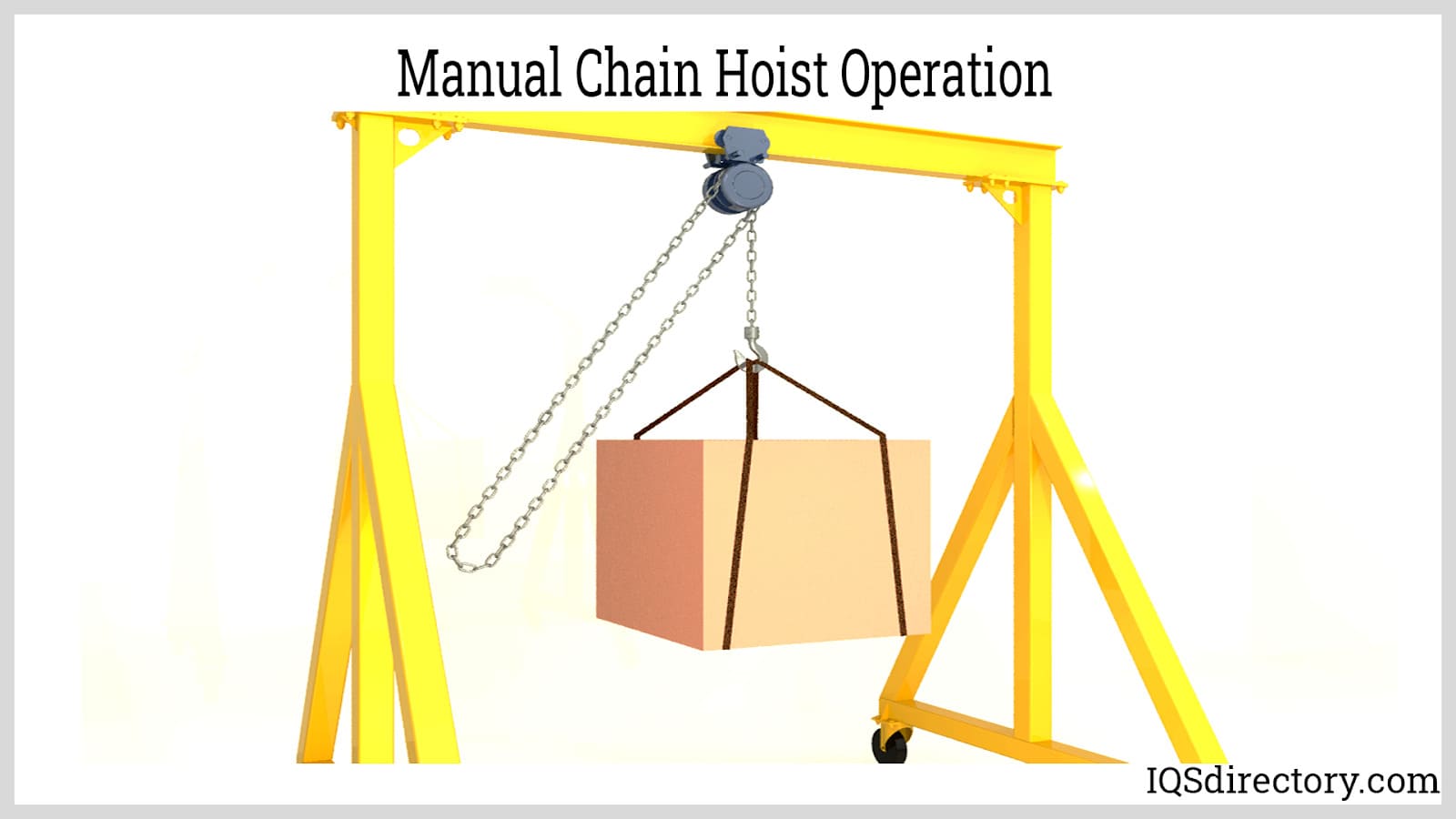

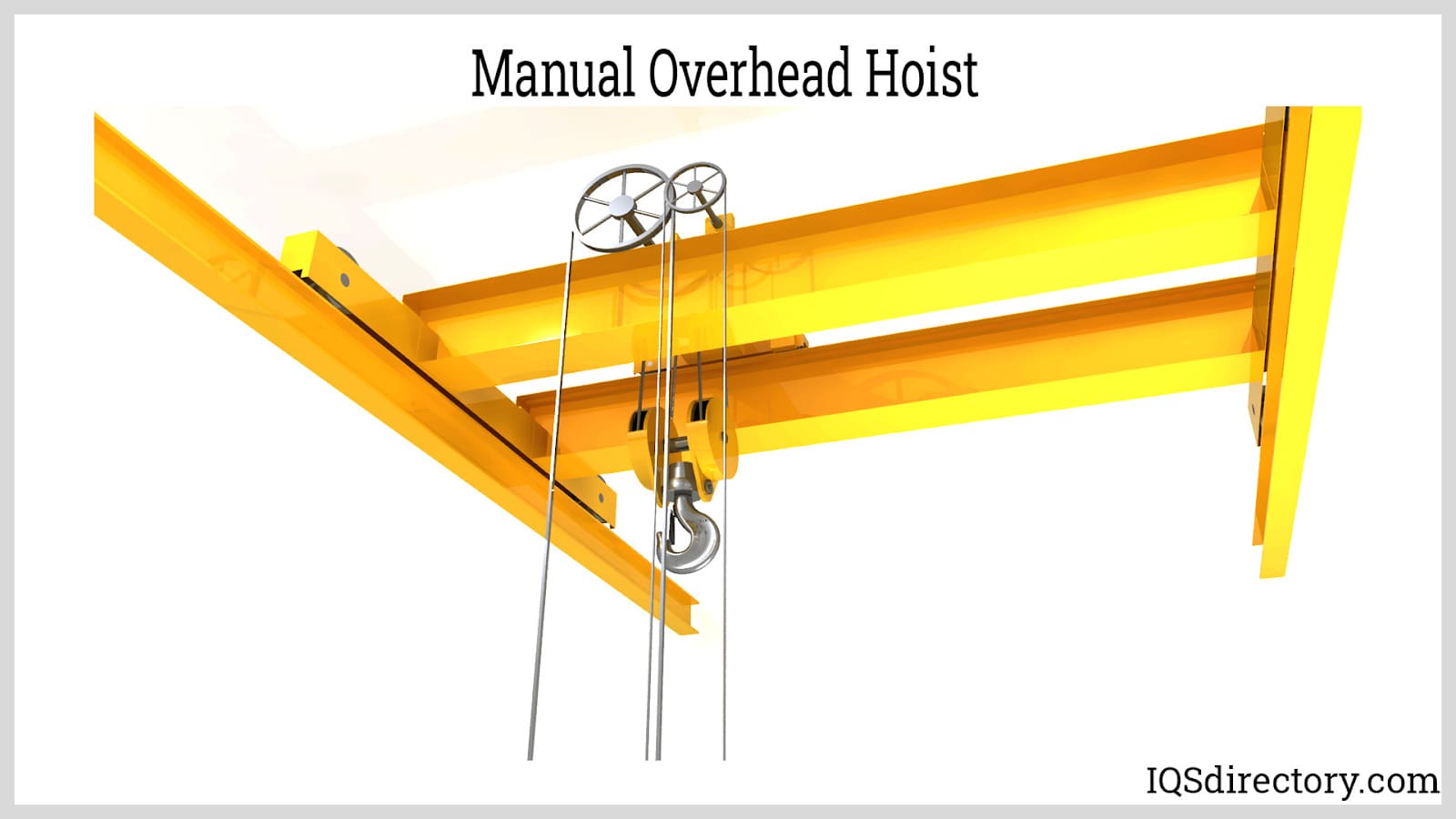

- Pulley Overhead Hoist – Pulley overhead hoists use wire rope and a lever lock or cleat brake to hold a lifted load in place. The hoisting mechanism for pulley overhead hoists can be gantry-mounted or ceiling mounted for easy movement and flexibility.

Types of Overhead Hoist Power Supplies

Overhead hoists are powered by pneumatic power, electric power, and manual strength. The type of power determines the lifting strength of an overhead hoist and can vary from simple to powerful designs.

- Manual Overhead Hoist – Manual overhead hoists are known as ‘chain and block’ hoists, fairy hoists, or hand chain hoists. They are the original form of hoists from the first industrial revolution. They use a chain and pulley mounted on a gantry. They can also be mounted on I-beams attached to columns or on the ceiling. Manual hoists are used for lifting tasks with loads under 1000 lbs. For example, they can lift vehicle motors or 55-gallon drums.

- Electric Overhead Hoists – Electric overhead hoists are powered by an electric motor and use a wired or wireless controller to adjust the lifting height. Electric hoists are the most powerful and are capable of lifting several tons. They are used for industrial applications with huge gantries or I-beam ceiling bridges.

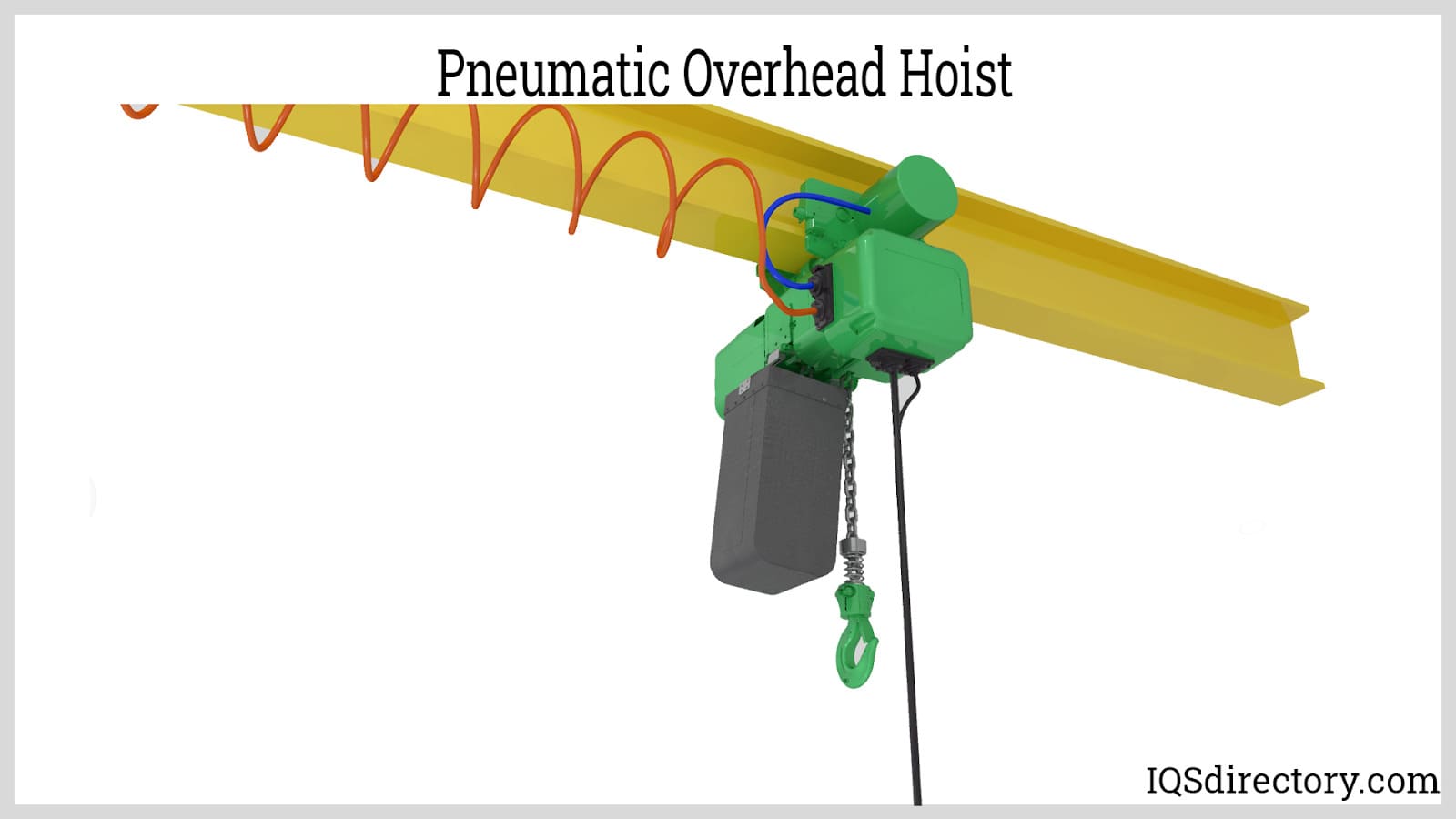

- Pneumatic Overhead Hoists – Pneumatic overhead hoists, referred to as air hoists, are powered by compressed air pressure provided by a piston or rotary-driven air compressor. They have a lifting capacity of up to 100 tons. They’re often on long duty cycles to operate continuously without the risk of overheating. Pneumatic hoists are used in environments that require explosion-proof equipment.

Overhead Hoist Suspension Systems

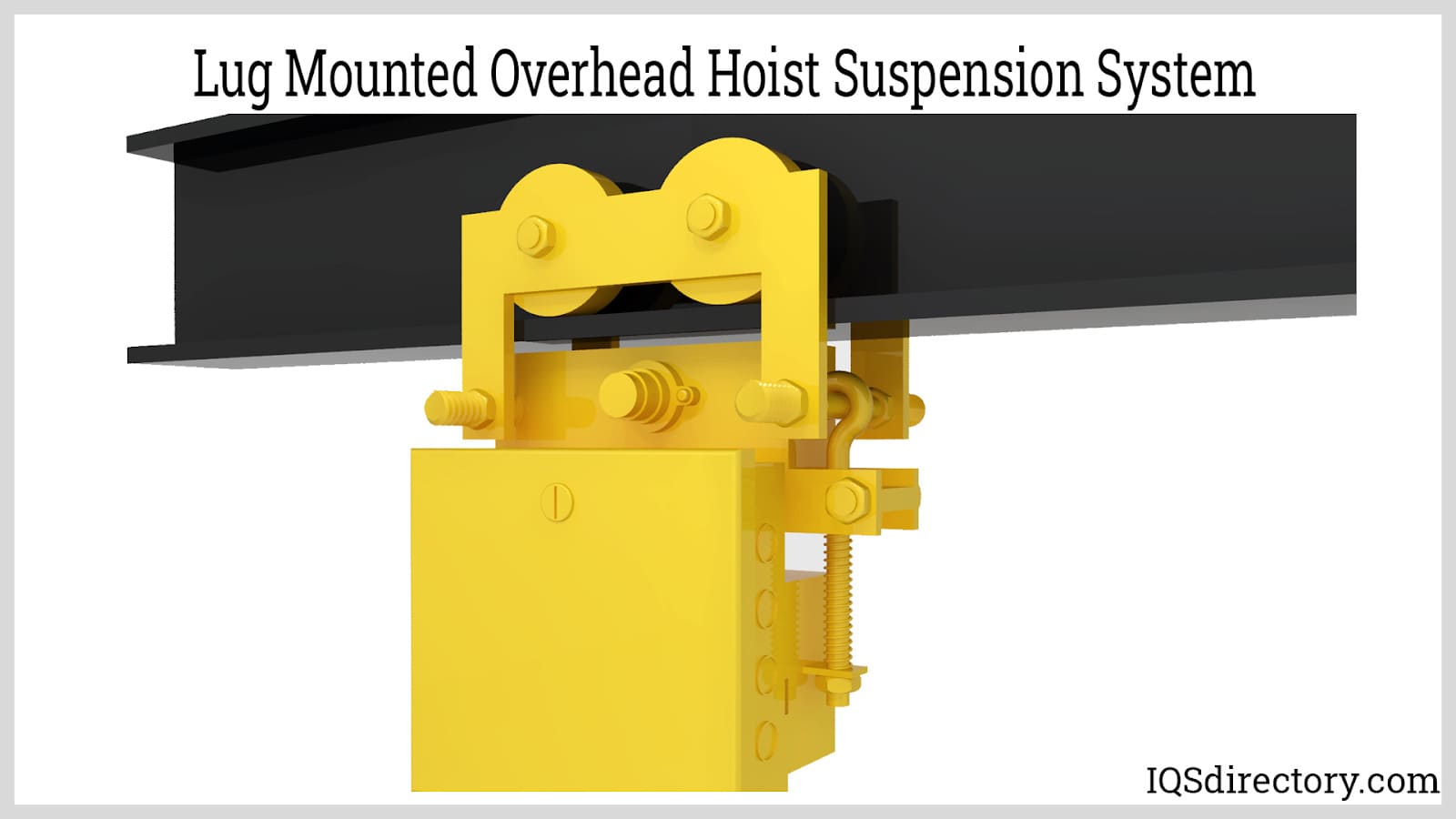

Overhead hoists are mounted on a rail system, or I-beams that move them from right to left. Complex mounting systems mount the hoist to an I-beam connected to a track. The track allows the hoist to move beyond a left-right motion. The suspension system connects the overhead hoist to a supporting system. Suspension systems are usually a hook, lug mounting, or clevis.

- Hook Suspension –In a hook suspension system, a hook is attached to the hoist frame or body. This connects the hoist to a trolley or fixed suspension point, like a boom extended from a wall. Additionally, hook suspensions can be attached to a fixture that is part of a building’s structure.

- Lug Suspension – Lug suspension systems have a mounting bracket attached or built into the hoist’s frame. Lug suspension overhead hoists can be electric or pneumatic.

- Clevis Suspension – A clevis suspension is a U-shaped metal bracket with holes in the prongs for a clevis pin. The U-shaped metal bracket and clevis pin suspend the hoist. Double clevis brackets have two U shapes connected at the curve of the bracket with pins in each set of prongs.

Overhead hoists are a material-handling tool used in warehouses, factories, manufacturing complexes, and shipyards. They are ubiquitous tools that provide the power and strength to transport heavy loads.

Choosing the Right Overhead Hoist Manufacturer

To ensure you receive the most beneficial outcome when purchasing an overhead hoist from an overhead hoist manufacturer, it is important to compare several companies using our directory of overhead hoist manufacturers. Each overhead hoist manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each overhead hoist business website using our patented website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple overhead hoist businesses with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches