Chain hoists are powerful and reliable tools widely used in various industries for lifting and moving heavy loads. These electrically powered devices offer a multitude of applications, making them indispensable in manufacturing, construction, warehousing, entertainment, automotive, and transportation sectors, among others. Chain hoists provide a safe and efficient solution for lifting operations, allowing for precise control and ease of operation. Read More…

Gorbel®, Inc. is an innovator and leader in producing bridge cranes for the industry. Gorbel® provides a wide variety of overhead handling solutions that handle loads from fifty pounds up to forty tons. Contact us today and we will work with you to find the best product for your unique application. Call or visit our website for additional information.

Crane-Tec supplies overhead cranes, hoists, jib cranes and workstations. Some of our hoists include chain hoists, overhead hoists and engineered hoists, and we have a variety of brands such as Yale, Harrington, EMH and more. Call us today for the hoisting equipment you need.

At Crane Equipment & Service, Inc., we take pride in providing a comprehensive range of electric hoists and solutions to meet the diverse lifting needs of industries worldwide. With our commitment to excellence and extensive experience, we have established ourselves as a trusted leader in the field of overhead lifting equipment. Our product lineup encompasses a variety of electric hoists...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

More Chain Hoist Manufacturers

Components of Chain Hoists

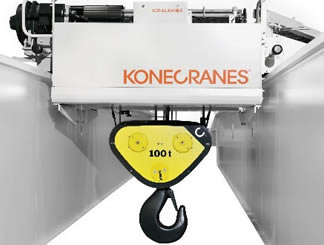

Chain hoists consist of several essential components that work together to facilitate smooth and secure lifting operations. The load chain, made of robust and durable materials, bears the weight of the load. An electric motor, meanwhile, provides the necessary power to drive the hoist. A control system enables operators to regulate the lifting process, ensuring precise positioning and control. Finally, a chain drive mechanism transfers power from the motor to the load chain, facilitating smooth movement. Additionally, safety features such as limit switches and overload protection mechanisms are available to enhance operational safety.

Variations of Chain Hoists

Chain hoists come in various configurations to meet specific lifting requirements. Single-speed chain hoists offer a constant lifting speed and are commonly used in applications where speed consistency is crucial, such as assembly lines or repetitive tasks. Variable-speed chain hoists, meanwhile, allow operators to adjust the lifting speed as needed, offering flexibility and adaptability in different scenarios. Low-headroom chain hoists are designed for spaces with limited overhead clearance, making them ideal for confined work areas. Finally, explosion-proof chain hoists are specifically engineered to operate safely in hazardous environments, providing reliable lifting solutions in industries such as oil and gas or chemical plants.

Considerations Regarding Chain Hoists

While chain hoists offer numerous advantages, there are some considerations to keep in mind. Initial investment and installation costs can be significant, particularly for large-scale applications. Additionally, regular maintenance and occasional repairs may be necessary to ensure optimal performance and longevity. It's important to note that chain hoists, being electrically powered and attached to fixed systems, have limited mobility and portability compared to other types of hoisting equipment.

Benefits of Chain Hoists

Despite the aforementioned considerations, the benefits of chain hoists outweigh these considerations. To begin with, chain hoists have high lifting capacities, allowing them to handle heavy loads with ease. Their precise control system also enables operators to lift, lower, and position loads with accuracy and efficiency. Furthermore, enhanced safety features, such as overload protection and limit switches, ensure operator safety and prevent accidents. Chain hoists are also designed for durability, with robust components that can withstand demanding working conditions, ultimately providing a long lifespan and a high return on investment.

Applications of Chain Hoists

Chain hoists find extensive applications across a wide range of industries due to their versatility and lifting capabilities. In manufacturing and industrial settings, for example, chain hoists are utilized for lifting heavy machinery, equipment, and components during production processes or for maintenance purposes. Construction and building projects additionally benefit from chain hoists by facilitating the movement of construction materials such as steel beams, concrete blocks, or prefabricated elements. Furthermore, warehousing and material handling operations rely on chain hoists to efficiently load and unload goods, especially in areas with limited space or height restrictions. The entertainment industry extensively employs chain hoists for stage rigging, enabling the precise positioning and movement of lighting equipment, audio systems, and set pieces during performances and events. In the automotive and transportation sector, meanwhile, chain hoists are indispensable for lifting engines, suspensions, and other heavy vehicle components, making repairs and maintenance tasks more manageable. The versatility of chain hoists extends beyond these examples, as their robust lifting capabilities and precise control systems make them suitable for diverse applications where heavy loads need to be safely and efficiently lifted and moved.

The Future of Chain Hoists

The future of chain hoists holds exciting possibilities as advancements in technology continue to shape the industry. One significant area of development is the integration of automation and smart features into chain hoists. We can expect to see increased automation capabilities, allowing for more autonomous and precise lifting operations. Advanced control systems and sensors may also enable hoists to adapt to different load conditions and provide real-time feedback on performance and safety. Additionally, the incorporation of Internet of Things (IoT) technology could enable remote monitoring and diagnostics, enhancing maintenance practices and minimizing downtime. Furthermore, advancements in materials and design may lead to the development of lighter and more compact chain hoists without compromising lifting capacities, thus increasing their versatility and mobility. As sustainability becomes a growing concern, we might also see the emergence of eco-friendly chain hoists that optimize energy consumption and reduce environmental impact. The future of chain hoists holds immense potential for enhanced efficiency, safety, and environmental consciousness, revolutionizing the way we approach lifting operations in various industries.

Choosing the Correct Chain Hoist Manufacturer

To ensure you have the most beneficial outcome when purchasing a chain hoist from a chain hoist manufacturer, it is important to compare several companies using our directory of chain hoist manufacturers. Each chain hoist manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each chain hoist business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple chain hoist companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches